Laser Automation

The fourth industrial revolution is transforming the world of manufacturing. To stay competitive

on an international scale, you need opportunities offered by digital connectivity. We provide you

with step-by-step assistance on your path toward digital manufacturing, offering pragmatic solutions

to help make your processes more transparent, flexible, and cost-efficient. That gives you the best

use of all your resources and securing your future in the manufacturing sector.

Table of contents

Software :

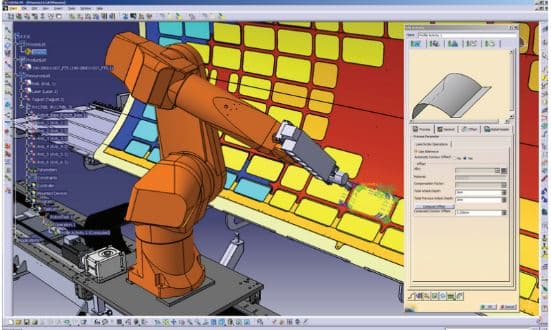

Offline programming made easy

Make it easy to program your laser welding cell offline, too. You can get straight down to laser welding thanks to the integrated standard optics. The system also allows you to mirror or reverse complete programs, saving you valuable

programming time. Modifications made to programs on the machine itself can simply be loaded back into the programming system, so you can combine the real-life manufacturing environment with the convenience of programming in your office. The software also works in the background to maximize

process reliability and manufacturing quality.

Lasers for manufacturing technology

Whether on a macro, micro, or nano scale, we can offer you the right laser and the right technology to create an innovative and cost-efficient production environment for any industrial

application. We can also provide you with appropriate system solutions, application know-how, and consulting services.

Advantages of 3D Robotic Laser Machine

for Metal with Fiber Laser Source

Robotic arm will assist the 3D laser machine to make flexible

3D dynamic of multi-dimensional and multi-angle for metals

with different thickness.

- The 3D Robotic laser machine is perfectly integrated with the world

famous robot and fiber laser technology, which

can realize the maximizing automated production. It will represent the

supreme laser technology. - 6 axis co-ordination makes a large working area, which will reach

a long distance, in addition, it has great ability of spanning and high

load-bearing capacity to ensure the process along 3D path

within the working space. - Due to slim robot wrist and the compact structure, so the 3D robotic

laser machine can realize high performance operation in a limited

space. - Laser speed can be adjusted to achieve the best machining

precision with high yield. - Long lifespan, long routine maintenance intervals, low-noise.

- The robotic arm can be controlled by handheld terminal.

- Packaging, handling, welding and other functions can be realized by

changing hardware and modifying the program.

- Laser Automation

- เทคนิคโลหะผงในงานเชื่อม Laser Cladding Powder

- ทฤษฎีการเกิดเลเซอร์

- Laser repair for high -value aero engine components

- Laser deposition technology